control System solution for Layer Winding Machine Accurate meter and weight measurement with an error of within 0.1%; Automatically decelerate and stop after reaching the set weight or meter; ■ Wire breakage detection and automatic shutdown; Realize constant tension and constant wire speed control during the winding process; Simple operation, high accuracy, and fast speed; Start and stop smoothly and quickly, without wire breakage; Various parameter settings, information display, and fault alarm functions; Scheme description: The PLC adjusts the frequency of the take-up frequency converter by simulating the output based on the detected linear speed signal and calculating it Changes with the roll diameter. When the wire is tangled during the layer winding process, it can also be controlled to reverse and rewind, and to release the wire rack during reverse rotation Automatically retract excess lines. The feedback signal of the Potentiometer is input to the pay off converter to control the constant tension Science and Technology Innovation Set the frequency source of the frequency converter to the main frequency plus the auxiliary frequency, with the main frequency set to 0 (set to AI1, and match AI1 with GND) The auxiliary frequency of disconnection is set to PID, and the PID target value is given by the panel (50%). Advantages of the plan: Active pay-off adopts bidirectional PID control, with fast response and constant tension; No need for coil diameter calculation and initial coil diameter setting for wire laying, saving detection steps (after encoder angular speed measurement) Calculate the roll diameter or directly measure the roll diameter using an ultrasonic sensor; Due to the addition of feedback signals from the swing rod to the PLC for auxiliary tension control, the pay-off reel will not There is a possibility of rapid forward and reverse rotation, so the discharge motor and frequency converter can be relatively small, saving costs; Feedback upper and lower limit detection is determined by the frequency converter and output, NO need to install a proximity switch for detection; Fast start stop, high production efficiency, fast speed (maximum speed 25m/s), stable and reliable operation; The system wiring is simple, the control logic is clear, and debugging is convenient;

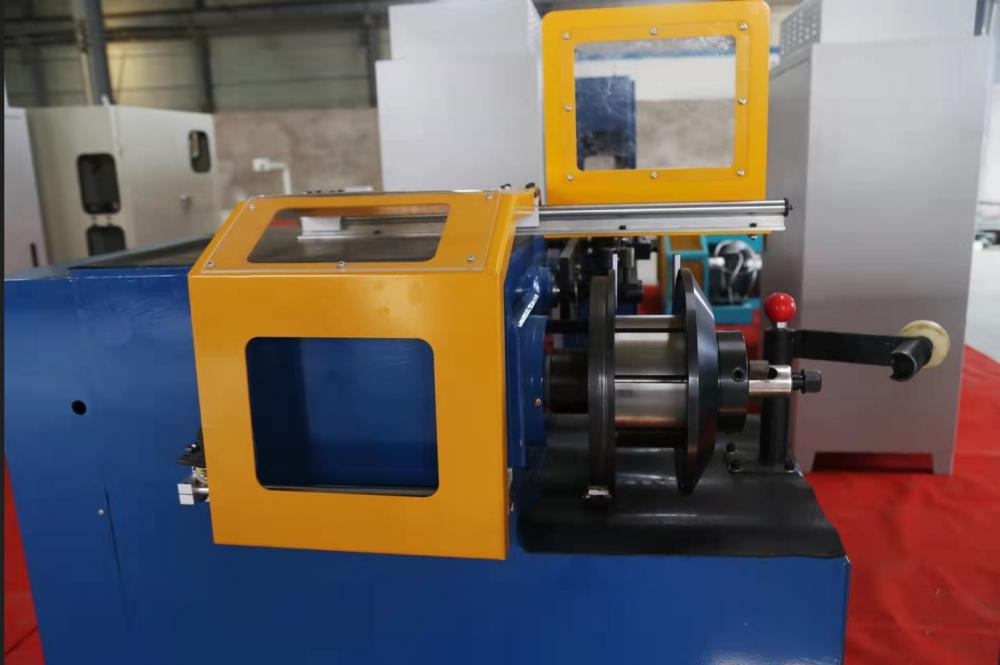

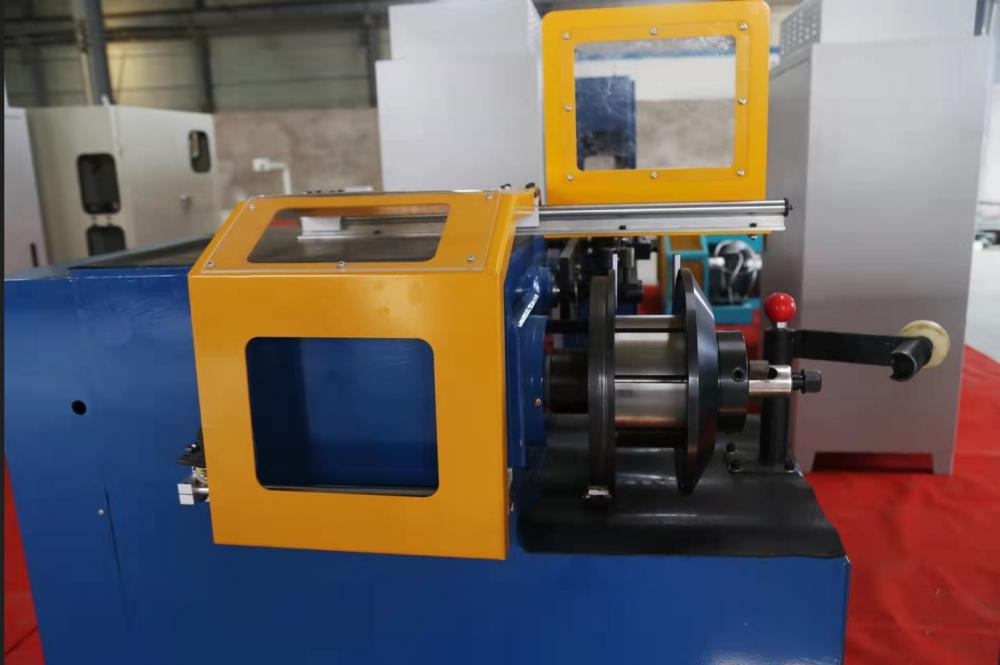

We can make the layer winding machine,Wire Drawing Machine,drum packing machine,take up machine,pay off machine,Flux Cored Wire Forming Machine.