Equipment Description:

1. 800 Payoff Machine:

[1] Adopting active wire laying technology, constant tension wire laying, variable frequency speed regulation, and wire laying motor 7.5KW.

[2] Adopting pneumatic top mounted I-shaped wheels, pneumatic brake mechanism, and equipped with pressure loss protection device.

[3] The body adopts a frame structure, with overall boring processing, and good working stability and stiffness.

2. 320 tension machine:

Using high-quality MC nylon, the outer diameter of the guide wheel is 320mm, with a configuration of upper three and lower two. The equipment is equipped with a displacement detection switch, pneumatic control for constant tension, and the tension size can be adjusted.

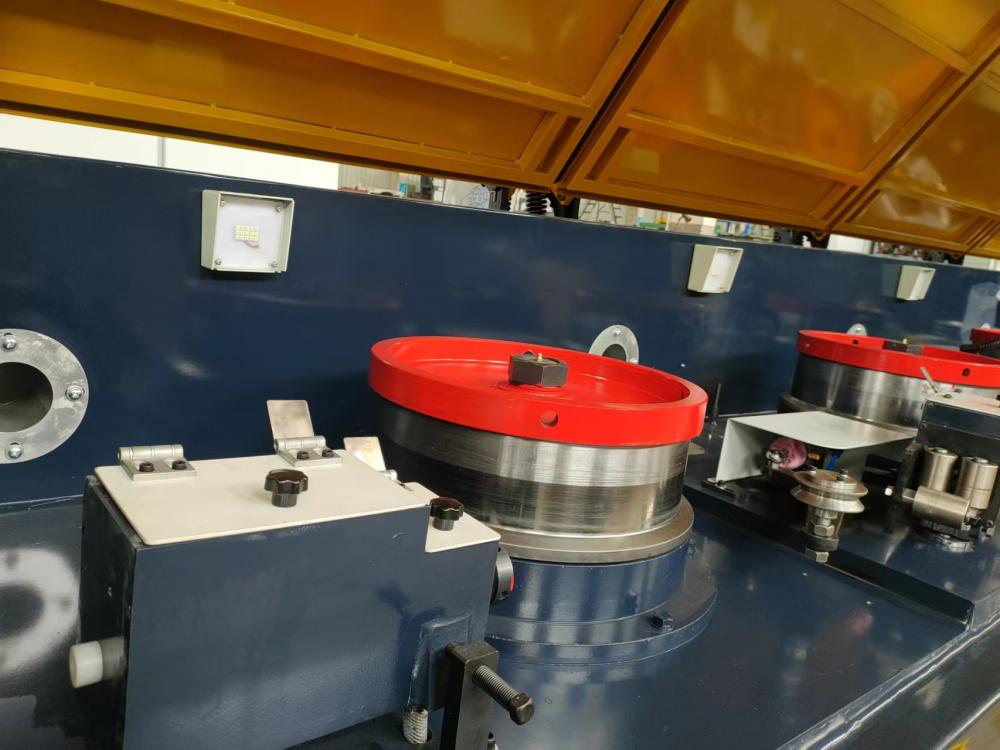

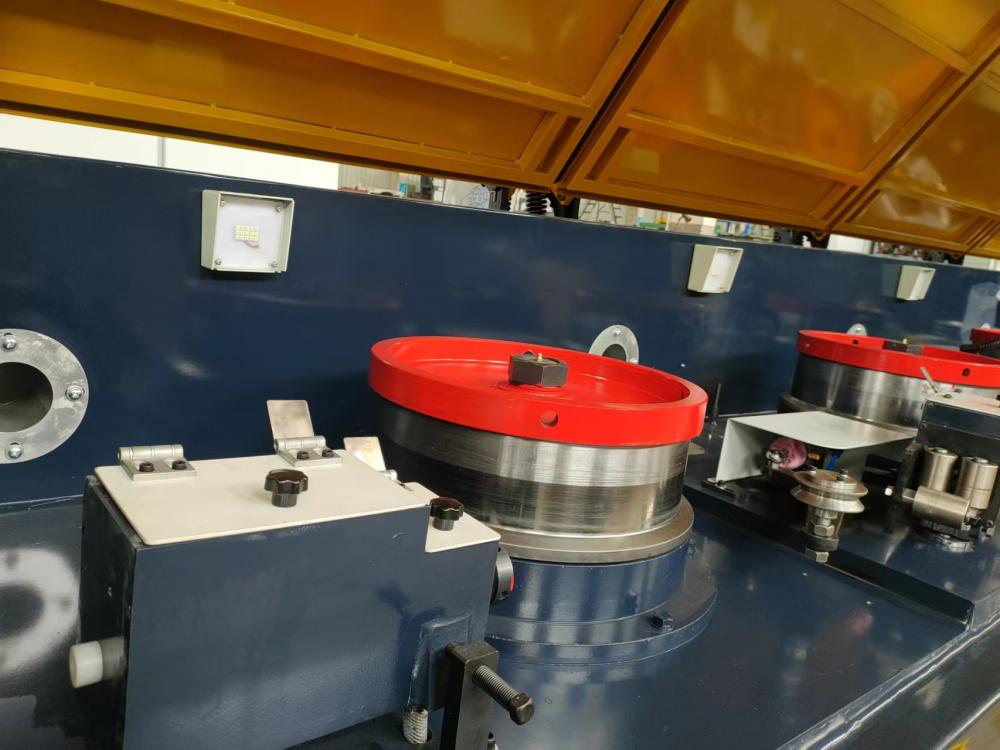

3. 400 tractor:

[1] The equipment adopts a horizontal structure for easy operation. The roller diameter is 400mm, the working surface is sprayed with WC, HRC ≥ 58, and the surface is finely polished.

[2] The equipment adopts variable frequency speed control, with a motor power of 5.5KW.

[3] The inclined mold box design allows for flexible adjustment in both horizontal and angular directions. The mold box adopts the method of manually adding lubricating oil.

4. Peeling machine:

[1] The overall steel groove structure, integrated peeling knife holder, adopts two peeling methods to effectively remove oil stains on the surface of the welding wire.

[2] The traction roller has a diameter of 500mm and is made of wear-resistant rubber material. It can be used on both sides, extending its lifespan by twice, and is matched with a nylon dividing wheel. The equipment adopts variable frequency speed regulation and drag, with a motor power of 7.5KW and a foot jog switch for easy threading.

[3] The equipment is equipped with three sets of circulation systems, one set of peeling tool circulation cooling, and two sets for wire drawing oil circulation lubrication. Each circulation system is equipped with a circulation pump and a lower box.

5. Belt cleaning machine:

[1] The equipment adopts a dual head structure, with the first head adopting a wet scrubbing method, equipped with a liquid supply box and a micro pump, and the second head adopting a dry scrubbing method.

[2] Each end is equipped with a tape release and retrieval system, which can be started, stopped, and operated separately.

[3] PLC control mode and touch screen control mode allow for flexible adjustment of parameters such as belt speed and liquid dosage as needed.

6. 800 winding machine:

[1] Adopting active winding technology, constant tension winding, variable frequency speed regulation, and motor power of 5.5KW.

[2] Adopting pneumatic top mounted I-shaped wheels, pneumatic brake mechanism, and equipped with pressure loss protection device.

[3] The body adopts a frame structure, with overall boring processing, and good working stability and stiffness.

[4] Using GP50 optical cable arrangement device, the width, stroke, and pitch of the arrangement can be flexibly adjusted.

7. Electrical control system:

[1] This set of equipment adopts PLC control for the entire equipment, with variable frequency speed regulation, touch screen control and display of working parameters.

[2] The equipment has functions such as start, stop, linkage, and joint stop, matched with a broken line parking device.

[3] The frequency converter and other electrical appliances of the entire equipment adopt a centralized cabinet installation mode, which is convenient for maintenance and technical management.

8. Safety protection:

[1] Each device is equipped with its own safety protection door, which can be closed and locked or latched during operation to prevent accidental damage during operation;

[2] The equipment is equipped with a pressure detection switch. When the compressed air pressure is too low, the equipment will alarm and stop working to avoid accidental damage.

[3] The equipment is equipped with emergency stop switches at the three locations of the pay-off machine, take-up machine, and stripping machine, making it easy to stop the equipment at any time in the front, middle, and back in case of accidents.

9. Rewind machine:

This equipment is used to roll the purchased cleaning tape from the market onto a plastic plate for easy use on belt cleaning machines.

The rewinding machine adopts a unidirectional motor to drive the winding, which can manually control the speed and force of the winding. It is equipped with a wire arrangement device to evenly wind the tape onto the plastic disc (i.e. 270 or 300 plastic disc), and the wire arrangement pitch and stroke of the wire arrangement device are flexible and adjustable.

We can make Wire Drawing Machine,drum packing machine,Layer Winding Machine,Flux Cored Wire Forming Machine,copper coating machine