Detailed description of the dual frequency conversion

Wire Drawing Machine system scheme and debugging

1. Preface

There are two schemes for the electrical system of the dual frequency conversion wire drawing machine: Scheme A: the main pulling motor and the winding motor are both driven by a universal frequency converter, and the synchronization of the stretching and winding lines is controlled by a PID synchronous control board. Option B: The main pulling motor is driven by a universal frequency converter, while the winding motor is driven by a dedicated frequency converter for the wire drawing machine with winding calculation, eliminating the synchronization control board.

Due to the increasing demands of customers in the wire drawing machine industry on the wire drawing process, the drawbacks of using PID adjustment control system in Scheme A are increasingly exposed: unstable tension at high speeds, excessive swing amplitude of tension swing rod when the disc diameter changes greatly, resulting in parking, insufficient low-frequency torque, and other issues; And adopting Scheme B, direct dual frequency converter control, eliminating synchronous control board, and utilizing the high-performance of current vector control frequency converter to achieve constant tension control at line speed. It has been proven that the control scheme using dedicated frequency converters for wire drawing machines exhibits good system stability and steady-state and transient control performance in the application of dual frequency converter wire drawing machine systems. Therefore, Scheme B has also been increasingly widely used in the online cable equipment industry.

2. Process requirements

Start and stop smoothly within the entire diameter range of the coil;

Stable operation within the full speed range, with small swing rod fluctuations;

The maximum speed can reach 2500 meters/minute;

3. Basic working principle of dual frequency conversion wire drawing machine

When the main traction motor is running, the frequency operation signal is converted into a standard analog voltage signal (or current signal) of 0-10V (or 4-20mA), and there is an analog channel output to the dedicated frequency converter for wire collection. This signal has two functions: one is to calculate the winding speed of the winding frequency converter based on the speed signal of the rewinding, and the other is to calculate the synchronous frequency signal F1 (V1=F1 * R, V0=W * R, V1=V0) of the winding frequency converter based on the synchronous speed signal V0 of the host. Notify this synchronous frequency signal to add another PID signal of the tension pendulum. Due to the adoption of a basic synchronous signal+PID adjustment method in the system, the PID adjustment amount is relatively small, and the system's working process is stable.

4. Debugging instructions for wire drawing machine (taking MD320-SL frequency converter as an example)

1. Set F4-13 and F4-15 based on the highest position feedback voltage and lowest position feedback voltage of the swing rod (assuming AI1 is selected for PID feedback), which can ensure that the swing rod is in the middle position when the PID is set to 50%.

2. According to the actual setting of the mechanical device, FH-01 (transmission ratio - motor speed/load speed) is set. According to the actual setting of FH-08 (maximum linear speed - refers to the corresponding linear speed when the analog input of linear speed reaches 10V).

3. When starting wire drawing, the swing rod is usually placed at the lowest position (if not at the lowest position, the swing rod will automatically return to the lowest position during startup), and then the swing rod will reach the middle position smoothly as the speed increases. Adjusting FH-15 (PID limit) and FH-16 (synchronous speed gain) can change the speed and delay of the swing rod lifting. The larger FH-15 is set, the faster the swing rod lifting speed is, and the negative FH-16 is set, the longer the delay of the swing rod lifting.

4. Run and observe FH-06 (coil diameter value). If there is any deviation, adjust FH-08. If the coil diameter is too large, it is set to be too large by FH-08.

5. The first and second sets of PID parameters can be adjusted based on the effect of speed (roll diameter). The first set corresponds to low speed (small roll), and the second set corresponds to high speed (large roll).

6. When changing the roll, the roll diameter should be reset.

5. Wire breakage detection function

When FH-21 is set to 1, a wire break is detected by the proximity switch signal. When the operating frequency is higher than FH-19 and the starting time exceeds the value of FH-18, a wire break is detected. After the wire break, the frequency converter reports an ERR24 fault. When FH-21 is set to 2, PID feedback (pendulum feedback signal detection of wire breakage) is used: FH-17 wire breakage detection lower limit value refers to the possibility of being in a wire breakage state when the feedback is lower than this value. FH-18 wire breakage detection start delay refers to the time after which the wire breakage is detected. The minimum frequency for FH-19 wire breakage detection refers to the detection of wire breakage only when the output frequency of the frequency converter exceeds this value. FH-20 wire breakage detection judgment delay refers to the output of a wire breakage signal after the current three conditions are met and the time has passed.

By configuring the above four parameters appropriately, the disconnection detection function can be disabled at the beginning of startup and adjusted in sensitivity and reliability. When the frequency converter detects a disconnection, it will report an ERR24 fault, stop freely, and then output a holding brake signal.

6. Control of holding brake

1. When the frequency converter detects a disconnection, it outputs a bandgap signal and releases the bandgap after the time set by FH-24. 2. When the machine stops normally, the frequency converter decelerates to the frequency set by FH-23 and outputs a holding brake signal. After the time set by FH-24, the holding brake is released. During the output of the brake signal, the running command is invalid.

7. High and low gear switching

By switching between high and low gear terminals, the corresponding relationship of line speed can be changed. On some medium drawing machines, pulling different types of wire requires switching between high and low gears. By setting the ratio of high and low gears, it can automatically adapt to high and low gears for smooth winding. Set the parameters first according to the parameters of a gear (standard gear). If the high and low gear switching terminal is invalid, control according to the set parameters. The function code FH-21 is the gear ratio coefficient, which should be set as the ratio of the highest line speed of another gear to the highest line speed of the standard gear. When the high and low gear switching terminal is effective, the frequency converter will automatically calculate its corresponding relationship.

8. Cable detection function

It is used to detect whether the flat cable is normal. If the detection is abnormal, the inverter reports ERR15 (external fault) and the flat cable part is installed with a proximity switch. The signal of each cycle of the flat cable is valid once. Judge whether the flat cable is normal according to the time set by function codes FH-34 and FH-35. FH-34 is used to detect whether the flat cable stops acting, and FH-35 is used to detect whether the proximity switch is invalid. Note: This specialized model has customized functions specifically tailored to the needs of dual frequency conversion wire drawing machines. Other unrelated functions of the MD320 are limited, and are hereby explained.

9. System Benefits

System simplicity: The frequency converter can fully achieve the main electrical control of the wire drawing machine without the need for an additional controller;

Simple debugging: Reasonable factory parameters can ensure adaptability to most usage situations;

Smooth start: Start logic control and coil diameter calculation functions to ensure smooth start under any coil diameter;

Full process stability: Two sets of PID parameters can ensure stable control effect of the entire swing rod;

Batch application is more convenient: the parameter copying function makes batch application more convenient and fast;

High and low gear switching: Equipped with high-speed/low-speed gear switching function, meeting the requirements of the medium pulling machine.

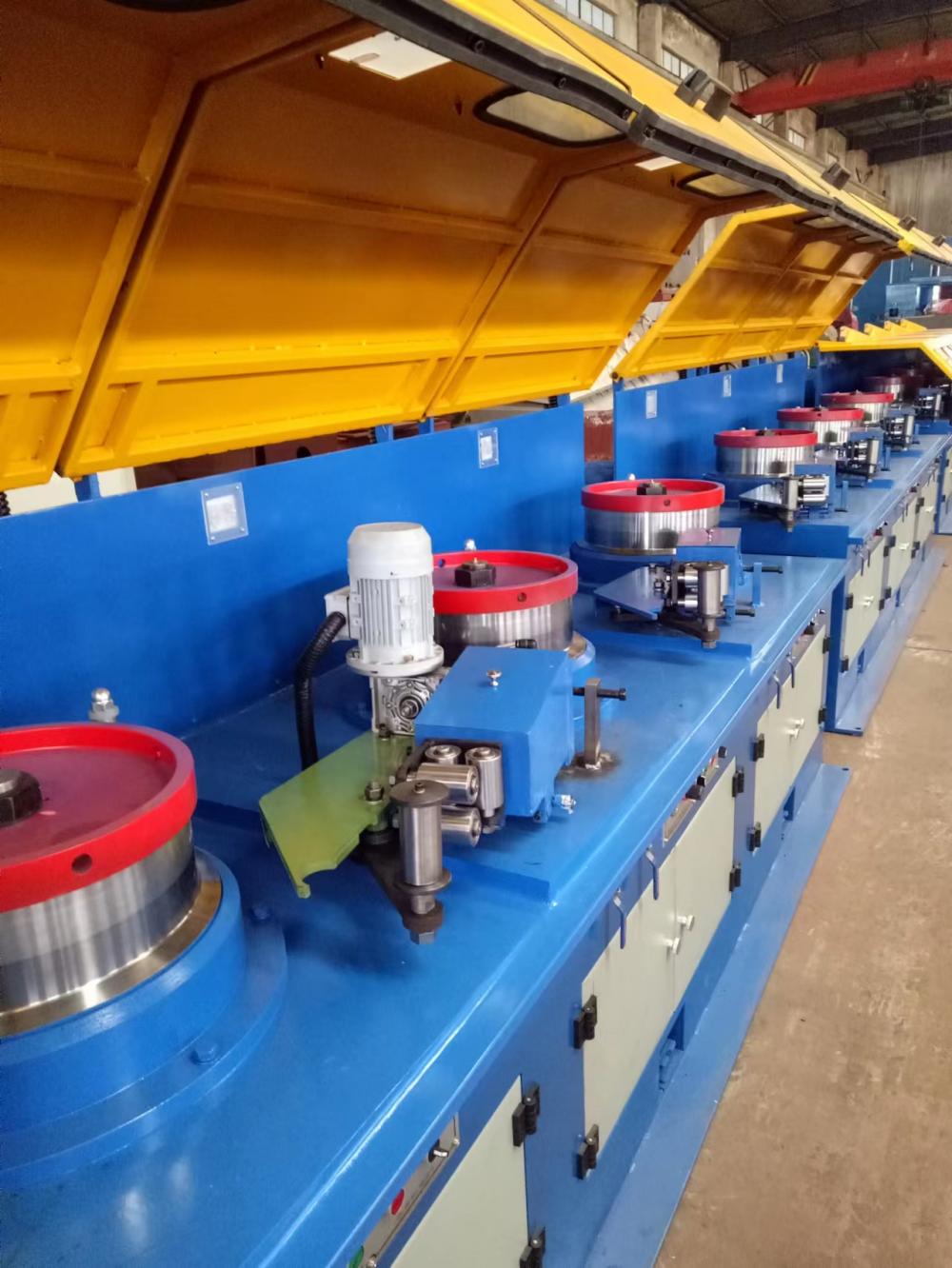

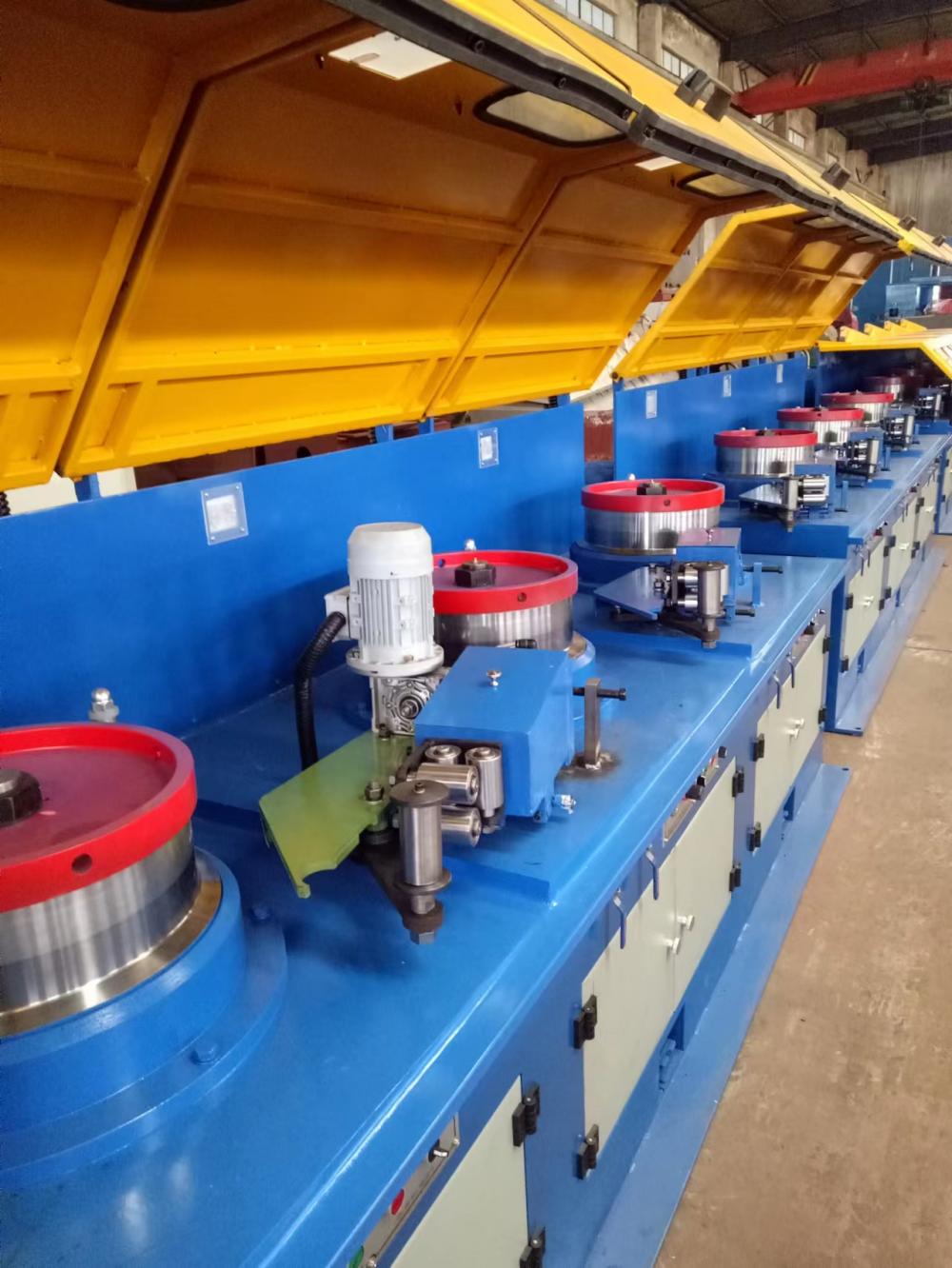

We can make the wire drawing machine,Layer Winding Machine,spooler machine,pay off machine,take up machine,drum packing machine,

Mig Welding Wire Production Machine