LZ Straight line wire drawing machine

$6000-150000 /Set/Sets

| Payment Type: | T/T,Paypal |

| Incoterm: | CIF,CFR,FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Land,Ocean |

| Port: | Shanghai,Tianjin ,Ningbo |

$6000-150000 /Set/Sets

| Payment Type: | T/T,Paypal |

| Incoterm: | CIF,CFR,FOB |

| Min. Order: | 1 Set/Sets |

| Transportation: | Land,Ocean |

| Port: | Shanghai,Tianjin ,Ningbo |

Model No.: LZ

Brand: Wanyi

Status: New

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Gearbox, Motor, Plc, Bearing, Engine

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Easy To Operate

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Applicable Industry: Manufacturing Plant

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Model NO.: LZ9-1200

Max.Inlet Wire Dia.: 14mm

Block Dia.: 1200mm

Max. Number Of Block: 9

Certification: Iso

Condition: New

Transport Package: Water Proof Plastic Film

Origin: Wuxi, Jiangsu

HS Code: 8463102000

Production Capacity: 100 Sets/Year

After-sales Service: 1 Year

Warranty: 1 Year

Type: LZ Straight-Line Metal Drawing Machine

Usage: Wire, Rope Wire, Prestressed Steel Wire

Metal Material: Steel

Outlet Diameter: 5.0-9.0mm

1. Company introduction:

Our company is a big private enterprise manufacturing various wire drawing machines with more than 25 years professional experience. We supply advanced Wire Drawing Machine and excellent after-sales service for Chinese and overseas metallic industry.

We manufacture Wanyi brand Straight Line Wire Drawing Machine series, wet wire drawing machines, inverted vertical wire drawing machines, combined wire drawing machines, OTO type (Pulley drawing machine ) wire drawing machines and relevant auxiliary machines.

These products are in an attractive appearance, reasonable price, stable performance, easy operation and production efficiency and with great safety. It has the emergency braking control, once there is something wrong with the working, it can be brake automatically.

2. Straight Line Drawing Machine:

Frame

It is the foundation of the whole drawing machine units. It is welded by buttress plate, bent steel, section steel. All materials are designed safety enough to enhance the rigidity.

Frame processing:

The frame stands on the special leveling welding plate, weld the steel as base of the bottom plate. Then do the low temperature tempering and vibrating treatment to eliminate the welding stress.

Cold machining precision is the important factor to realize the high-speed drawing. Do the milling process for the bottom plane and connecting side of the frame. Then clamp the main hole and screw hole of the mounting surface.

Machining ended frame closures group in the painting shop, pain the anti-rust primer and do the scraping and deburring.

Lastly, paint second time topcoat painting according to customer's color, wait for assembling.

Capstan structure

Material is ZG45 steel casting blank body, after quenching and tempering treatment, HB250. Dig 5mm depth on the working surface of capstan, then melt the tungsten, cobalt carbide, overlay welding. Then rough lathing, precision lathing, grinding and polishing, surface roughness can reach to 0.08μm, hardening layer height 300mm, depth more than 3mm, HRC 58-62.

All the surface of capstan is processed by lathe, non-contact and operation surface's roughness is 6.3μm, capstan inner wall sprays zinc, can effectively reduce the formation of cooling water scale.

Capstan spindle hole against axis beating up tolerance is ±0.03μm, capstan dynamic balance level is G6.3.

All the surface of capstan is processed by lathe, non-contact and operation surface's roughness is 6.3μm, capstan inner wall sprays zinc, can effectively reduce the formation of cooling water scale.

Capstan spindle hole against axis beating up tolerance is ±0.03μm, capstan dynamic balance level is G6.3.

Capstan cooling

The main shaft of capstan is fixedly install an upper spiral water jacket, below is a water wheel. Capstan is mounted on the spindle, the lower part of water jacket and capstan inner wall form 10-15mm water storage. Circulation cooling water from the upper o water jacket to capstan inner wall, the water cabin is filled with cooling water will adequately cool the wounded steel wire. When capstan rotating, spiral groove will keep the cooling water to rise, then flow down along the capstan wall, discharge the water through the upper outlet, forming good circulation water cooling.

Drawing Dies

The drawing dies, besides the finished rolls, all rolls about 8 ° tilt to keep the wire reel maximum amount of plot lines and wire straight toward. Tuning rollers apply anti-pull the wire, to reduce mold drawing force.

Die box is welded structure, into two cavity. The guide roller is mounted into the side to ensure that steel wire can straight into the drawing die, die holder should be adjusted to wire tangent to enter the drawing rolls tuning roller installed at the entry end of the mold base tuning roll by a small cylinder put power, tuning the swing of the roller, so that the corresponding sensor output signal to fine-tune the speed of change. Tuning roller wire tension by adjusting the air pressure change, regulation range 0.15-0.6Mpa. The mold box is also equipped with a stirring device. Tuning roller side of the mold box, a gear reducer single-phase capacitance running motor through a sprocket, power passed to the stirring arm to stir the mold box, lubrication powder, without agglomeration affect lubrication.

Safety shield

The shield uses whole closed structure which is welded section steel and steel plate. Façade designs hopper and transparent window with 10mm thickness polycarbonate plate. Use hollow rubber strips around the shield to protect and serve as a buffer.

Fulcrum design balance spring mechanism, through adjusting the balance spring pivot position, can achieve the shield is closed lightly.

Shield is provided with protective contact switch. It's a device for realizing mechanical locking at run time. (When machine is running with shield opened, the unit immediately drop speed running or parking, recover normal after closing it. When it opens, the unit can only jog.)

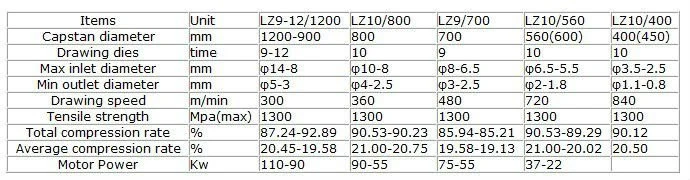

3. Wire drawing machine parameter

We can make wire drawing machine,Flux Cored Wire Forming Machine,drum packing machine,pay off and take up machine,Layer Winding Machine,and so on.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.